Customized Systems – tailored to your requirements

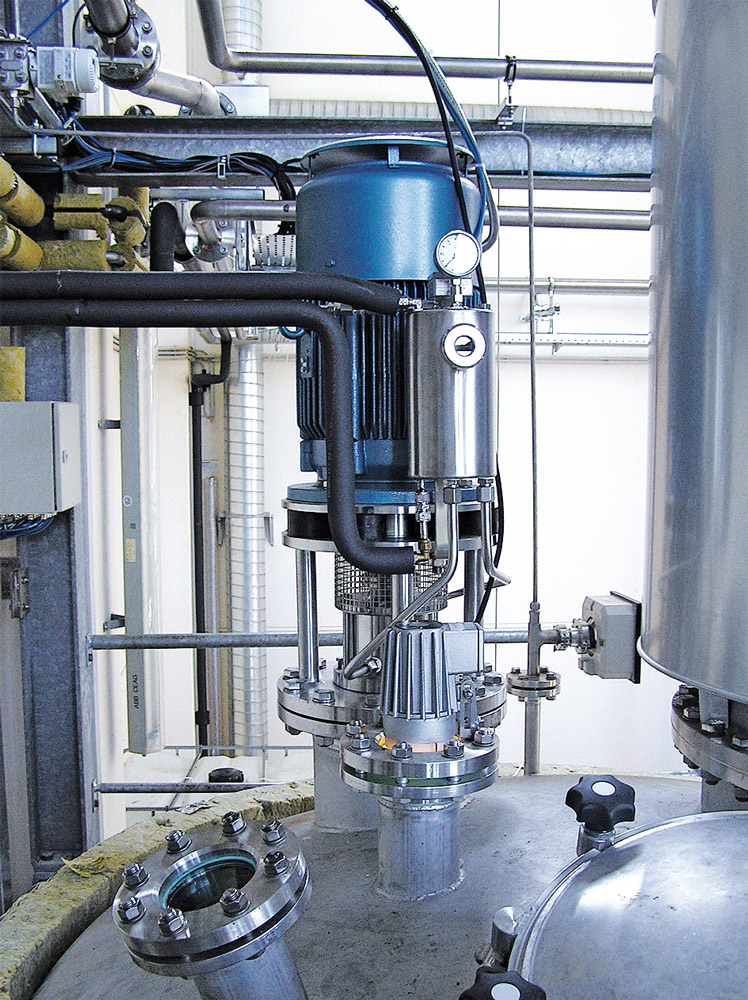

Distillation System

Reboiler capacity 6,000 ltr/

Column dimension DN 700

Customized Design for

Purification of Essential Oils

Scale-Down Design

Linear Alpha Olefins Pilot Plant

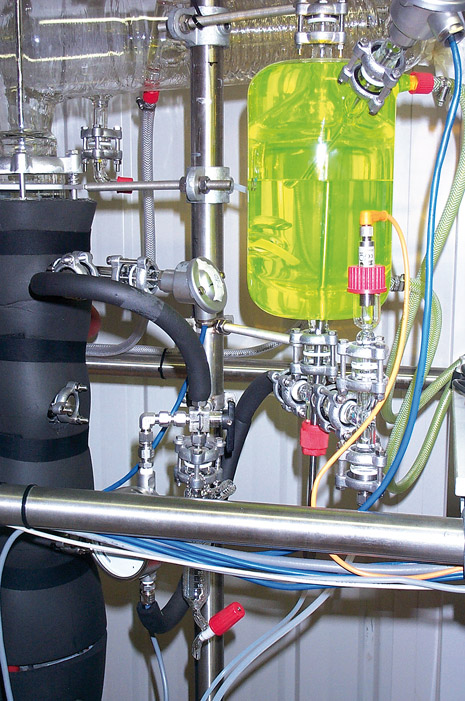

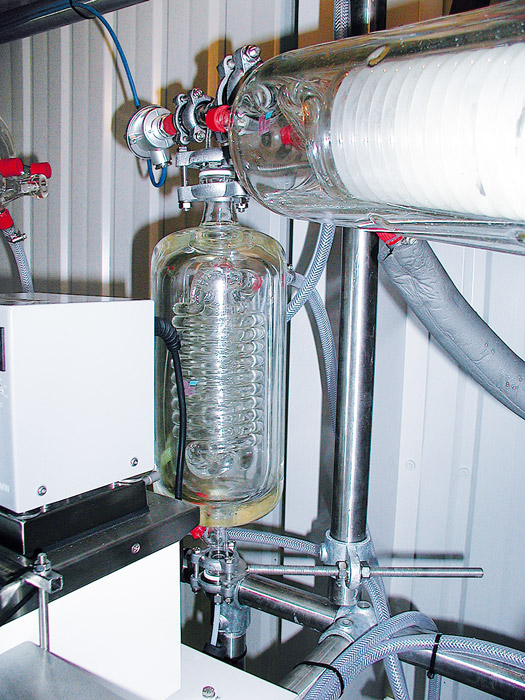

Lab-Scale Distillation Unit for universal use to determine distillation data for upscaling.

The unit is equipped with an inert gas distributor, borosilicate glass 3.3 with PTFE valves and safety valve. Due to the complex design it is possible to evacuate or to flush the distillate receivers by inert gas. The evaporator is heated by heat transfer oil, preferred for smooth heating and handling of heat sensitive products. The separation column with its high efficient structured packing SULZER EX in Hastelloy combines high separation efficiency with excellent chemical resistance.

Batch Distiller with SULZER packing, Controller ILUDEST® [DC/MIC]³ and Vacuum System for solvent recycling and research purposes.

The unit combines well known distillation technique with modern micro-electronics. The touch-panel based controller is able to handle receipts for different mixtures. The distillate can be discharged into several final receivers as pre-cut and product cuts. Distillation rate can be measured via an intermediate receiver of fully automatic by a volume follower.

Highly efficient

Through judicious selection of the appropriate components we achieve best standards of efficiency at high throughput rates.

Operator friendly

Simple and convenient operation of the plant with the highest possible safety standards through the use of high tech electronic measuring and controlling modules.

Operation safe

Temperatures, pressure, filling levels and cooling water as well as utility supply are monitored. We can supply explosion-proof plants or equip plants with safety housings, fire protection troughs and fire extinguishing systems.

Economical

This modern distillation range is noted for its diversity and effectiveness: Distillation components designed as modules for combination and variation according to existing needs. The automatic operation of ILUDEST® plants saves the user unnecessary expenses.

Adaptable

We will match the modular system to your specific problem, irrespective of whether you are working with solvents, aromatics, acids, chlorinated hydro- carbons, petroleum fractions or simply water.

Complete solutions as turn-key jobs

From a round bottom flask with distilling link to the fully automatic, computer controlled pilot plant.